What Is A Volleyball Made Of: Everything You Want To Know

Volleyballs are round and traditionally consist of eighteen nearly rectangular panels of synthetic or genuine leather, arranged in six identical sections of three panels each, wrapped around a bladder.

Volleyball is one of the most well-liked sports today. No one can discount that the most important part of the game is the actual volleyball ball. The ball has been the focal point of play ever since the game’s creation in the late 1800s. The main objective of any player, whether on a professional team or a hobbyist team, is to learn how to move and control the ball.

Please continue reading as I provide more detailed information about the materials used to make volleyballs.

Table of Contents

What Is A Volleyball?

A volleyball is a piece of volleyball equipment together with shoes, volleyball knee pads etc. The different floors where the game is played are specifically made for volleyball. A ball made for beach play is very different from one made for a court floor. Consistent features include the ball’s round shape and the arrangement of 18 rectangular-shaped panels of leather, either genuine or synthetic, on six different panels. Around the ball’s bladder is wrapped a leather covering. It’s intriguing that, due to the way it’s made, depending on the team using it, it can adopt a variety of fun colors. You can recognize it as a volleyball because of its distinctive appearance, but it can also be dressed up when appropriate.

The FIVB, a governing body that established the rules and regulations, was founded in 1947 by France. That implied that the volleyball would be used consistently throughout matches. Imagine if the balls that the teams used were of varying quality. A player’s reaction and control can be significantly altered by even a small difference in mass and flight ability. Try playing volleyball with a youth-sized ball and then a standard one. The differences between them are immediately clear. However, that doesn’t mean a smaller ball isn’t still valuable in the game. They are excellent resources to use when the game first begins. If you’re focusing your new player on learning control and going through drills, a lighter ball can help dramatically. When they reach the larger courts, however, they must adapt to playing with a standard ball and learn how to adapt their techniques to the bigger, heavier ball.

The FIVB continued to play a significant role in the growth of the game. In 2008 they decided that the Mikasa ball with eight panels and with dimples in the body would be the official indoor ball for volleyball sports. Its softer-to-the-hand feel and more streamlined flight capability made it particularly practical for indoor play. Additionally, a valve that allowed the ball’s internal air pressure to be changed was included.

How Are Volleyballs Made?

Starting with a sheet of natural rubber, most sports balls are constructed similarly. This is then folded in a specific configuration, and then a die is placed on top, which helps force it through the layers and cuts out the shape of the ball. The ball’s bladder is created as a result.

The next step is to insert a plug after applying adhesive to the bladder hole.

The rubber bladder is then placed in a sphere-shaped chamber, where heat and curing agents are applied to the rubber. It picks up nylon threads while spinning on a rotating cylinder while being heated. These encircle the bladder in a twisting motion, forming the layer that not only keeps it spherical but also fortifies it.

For the outer layer, materials like rubber or synthetic rubber that have been cured will be sliced to a specific width and folded several times. In order to flatten the folded rubber and make it lightweight and malleable, it will be run through a number of rollers.

Rubber is cut into thinner pieces by an automated blade, then it is divided into strips by a metal pattern cutter. These combine to create the ball’s exterior. After that, strips are produced and positioned using a bonding shaper. The bonding chamber is then sealed and turned on after the bladder has been inserted and reinflated.

Following that, the strips adhere to the bladder due to heat and pressure. After cooling, the ball is taken out of the bonding shaper.

Volleyball Materials

The materials used to make volleyballs are what differentiate one volleyball from another. Balls made of inferior materials are of poor quality. You’ll notice that they have officially approved volleyballs if you look at the balls that are approved by the FIVB or other professional organizations supporting the sport. They do this because they want to provide the best equipment for their players, which will allow them to truly demonstrate their skills and labor of love. The ball is composed primarily of three parts:

The Outer Shell

Usually, a high-quality leather or a synthetic leather is used for the outer shell. Different panels that are securely glued to the inner lining are used to construct indoor volleyballs. This is a technique for making the seams appear smoother. This smoothness benefits the court’s surface because if a heavy seam were to contact it, the ball would veer off in an unanticipated path, likely putting the player in a challenging, if not impossible, situation. It must be smooth for the ball to move in an expected manner so the player can control it. Beach volleyballs and outdoor volleyballs are constructed from panels that are fastened to the inner lining. You can see the threads, holes, and how the panels are used to hold the ball together if you look at it closely. Smoothness is still desired for the ball in an outdoor setting, even though it is not given as high of a priority.

The Core

The ball’s “bladder” is the name given to its center. Typically, a rubber core is used to make it. Its extreme lightness is the cause of this. It’s important to keep in mind that most volleyballs weigh between 9.2 and 9.9 ounces, leaving little room for a substantial core. This gives players the ability to work with the ball without exerting themselves, in addition to allowing the ball to fly through the air more easily and smoothly. Just picture a player who has repeatedly been hit in the arms. You likely will see a person with very red forearms. This might have been far worse for the player without the ball’s lightness.

The Panels

A volleyball’s exterior used to be surrounded by 18 panels in the past. However, the official balls used in the Olympics and other professional leagues are tricolored and have eight panels. The panels are there for a variety of reasons, but it’s important to note their impact. They aid in the ball’s cohesiveness and playability by keeping it streamlined.

One of the most important pieces of equipment in volleyball is the ball. What if it were weak? Consider that flimsy ball competing in a championship game against elite athletes. Playing with a regular ball to help you win wouldn’t produce the same results, by any means!

Volleyball Ball History

When William G. invented the game, volleyball itself was required. A net and a ball were used in Morgan’s 1895 design of the game. There were some volleyballs available at the time, but they weren’t exactly appropriate for the high-performance sport. A ball that was appropriate for the environment was necessary for the various moves required to control the ball. Consider what a volleyball must do in any given game:

- It has to be kept airborne throughout a play

- It has to be light so that it can be kept airborne

- It can’t be so light that it is easily shifted by winds

- It also can’t be so light that it only moves slowly due to resistance

There weren’t any balls that perfectly fit the bill as Morgan required when volleyball was invented. Initially, volleyballs made from a basketball’s bladder were used by players and teams. However, due to its lack of weight, a basketball’s bladder proved to be too slow in the air. Basketballs were used as makeshift balls by some players. Again, the weight of the balls prevented them from maintaining the necessary air pressure, so this didn’t work out too well.

Finally, Morgan went up to A.G. Asking Spalding and Brothers to create a special volleyball that would serve as the official volleyball. Spalding was a well-known figure in baseball at the time. They were the ones with the knowledge to design a new ball that suited the requirements of this more recent game. In its original form, the volleyball ball had a latex bladder made of a substance resembling a bicycle tire. It was surrounded by another layer of fabric that resembled cheesecloth in the second layer. A third layer of leather, which was sewn around the ball, was placed on top of that.

The makers of Spalding applied their knowledge of baseball to the sport of volleyball. The ball was not too heavy, but it was more streamlined and solid for excellent flight. In comparison to their original design, volleyballs of today have not undergone much change. The fact that they actually worked negates the need to recreate them.

However, the outer panel of the balls has changed. Originally, an 18-panel construction was used to stitch the leather outer covering to the inner bladder. If you look at historical balls you can see the distinct look of the ball. With these multi-panel designs, it was simple to imprint logos and various colors on the ball. The appearance changed in 2008 though. The planned Olympic Games provided the catalyst. A pioneer in the volleyball industry, Mikasa developed and produced a newer design that allowed for the best possible hand-ball contact. This new style had eight panels. The newer, less-paneled ball was found to offer players greater accuracy after testing. Additionally, it was designed with dimples that complemented the ball’s flight path. Intriguingly, this was the first time in the volleyball’s 100-year history in sports that the design had changed.

Modern balls are now required to be between 9 and 12 ounces in weight and 25 to 27 inches in circumference. This standardization began in 2008. These are the general rules for balls used in many training sessions and in all professional sports. With only a few minor modifications over the past ten years, the actual volleyball has remained true to its original design.

Volleyball Balls Evolution

The first official indoor volleyball, which had a circumference of 65 cm and was made of genuine leather, is credited to have been produced by the Spalding Sports Company. It had an average weight of 270 grams with an air pressure of 0.325 kg/cm2. The first synthetic materials were released later in the early 1900s. These were used to reduce the harness factors that over time formed on the leather surface. The synthetic leather also improved the ball’s longevity and durability and contributed to the air pressure’s prolonged retention.

Three distinct layers can be found on a traditional volleyball. The material used to make basketballs was previously used to build the bladder’s innermost layer. Its drawback was that it added weight to the ball and slowed down its rate of flight. The balls were later changed by Spalding Company using latex rubber. The balls became flexible, lighter, and air pressure resistant thanks to the new material. Traditionally, cheesecloth was used for the second layer.

Additionally, it was changed by utilizing a woven material with a higher density and better grade. Genuine leather has always made up the final outer layers, though this was later changed to a synthetic material. Eight dimpled panels were originally on the balls, which were perfect for indoor matches. Recently, though, balls with up to 32 panels have become popular and are perfect for use on any surface, from hard ground to sand and indoor courts.

The valve design also changed over time as volleyball balls evolved. By letting the extra air out, the players can now change the ball’s air pressure. Players had to use the cycle pump to bloat the ball at first, so the air pump underwent a number of changes as well. To inject air into the bladder of the ball, players now employ cutting-edge techniques.

Indoor Vs Beach Volleyball Balls

The environment is unquestionably an issue with volleyball. In terms of the ball, what works indoors does not work on the beach. To accommodate the challenges it faces, each setting needs a unique ball. There are two settings in particular: the beach and the indoors. Just consider how dissimilar each is, and you can easily picture the various types of gear required for each.

The Indoor Setting

A court floor is part of the volleyball environment indoors. These balls can either be all-white or come in combinations of two or three colors. Two distinct fashions exist: youth and adult. The youth volleyball ball for indoor use is 63 to 65-centimeters or 25 to 26-inches in circumference. They have a weight of 260–280 grams, or 9.2–9.9 ounces. These balls have an internal pressure of 4.3 psi, or 0.30 kgf per centimeter squared. The adult indoor volleyball ball is 65 to 67-centimeters or 25.5 to 26.5-inches in circumference. They measure 260 to 280 grams, or 9.2 to 9.9 ounces. They have a psi of 4.3 to 4.6, or 0.3 to 0.325-kgf-per-centimeter-squared. When comparing the two, the numbers don’t show much of a difference, but there are significant differences between the play styles of adults and children. Keep in mind that kids must be able to palm the ball and drive it over the net. They can succeed much more easily if they are slightly smaller and have a lower psi. You’ll see that both balls have an extremely streamlined and lightweight appearance. Once more, this is to make it easier for the balls to move during a fast-paced game where timing is crucial.

The Beach Setting

The ball has to withstand many outdoor elements during a game of beach volleyball that it won’t encounter when playing indoors. The sun’s heat, UV rays, sand, and other environmental factors. The psi requirement is entirely altered by these. The diameter of beach volleyballs ranges from 66 to 68 centimeters, or 26 to 27 inches. They weigh 9.2 to 9.9 ounces, or 260 to 280 grams, on average. Their pressure setting is 2.5 to 3.2 psi, or 0.175-0.225 kgf per centimeter squared. You’ll observe that the only significant distinction between the outdoor ball and the psi is this. Due to the surface that the ball must bounce off of, this has happened. A lower psi is necessary to accommodate effectively because sand differs greatly from a courtroom floor. The beach volleyball ball is also a little bit bigger and has a rougher exterior than indoor balls. The game’s outdoor requirements are perfectly served by this coating.

It is crucial to practice and play volleyball with the appropriate gear, which includes a ball made for the environment in which you will be playing. This can have an impact on your entire performance and give you the advantage you need to win. If you are using the incorrect equipment, including the ball you choose for your game, having the wrong ball or practicing with one will be very different strategically.

Volleyball Speed & Reactions

The speed of volleyball balls, whether played indoors or outdoors, and how it affects reaction times are two of the main issues. According to recent studies, professional players can spike the ball at speeds of up to 80 mph! It takes a few things to make that incredible feat possible; first and foremost, the player must be very skilled. It also needs a lot of power and the ability to know where to use that power, which is the second requirement. It also requires the proper ball construction. The manufacturers of them play a role in this. They do extensive studies on what works, and what doesn’t in terms of optimizing the performance.

According to records, it was Matey Kaziyski of Bulgaria who set the world record spike of about 80.1-miles per hour. Despite the fact that that is the top speed, collegiate competitions typically reach speeds of 50 to 60 miles per hour. The typical high school athlete runs between 40 and 50 miles per hour. The fact is that over time, players gain the ability to spike the ball much harder thanks to their development of skills. The ball moves at a certain speed depending on how well the player executes the strike on the ball and how well they use technique. The ball’s final speed depends on the player’s body angle, how hard they strike it, and how they connect their hands to it. Because the best players can be valuable offensive contributors to the team, this is a highly sought-after talent. A teammate who can attack quickly and effectively can defeat any block and typically keeps the opposing team’s defense on its toes.

Spiking requires a quick response time from the opposing team, which is what makes it so beneficial for a team. Imagine how much more natural talent is needed to catch a ball that is falling to the ground at 40 mph than one that is falling at 60 mph. The other team’s defense actually jumps when the faster ball is used. They risk losing if they don’t have enough time to properly position themselves for their shot.

One thing that volleyball players work on over and over again is their reaction time. Coaches will use 2-point start drills and wall drills to work on a player’s response. The intention is to make the actions automatic so that the players won’t even consider their reactions when the big game is underway. Their bodies respond by moving quickly. However, it takes time to develop this level of dexterity, so if you intend to play the sport, plan on devoting a significant amount of time to mastering the volleyball’s handling techniques.

Major Volleyball Producing Brands

The top five volleyball brands in the world right now are:

- Mikasa

- Tachikara

- Molten

- Wilson

- Spalding

Mikasa

Mikasa is a ball manufacturer based in Japan that supplies professional athletes with the equipment they need for competitions like the Olympic Games and the World Championships.

Because they use the best materials available, their products are well-known for their high quality. They also feature grip technology, which helps with control on the court.

Although their balls are somewhat pricey, many people think the investment is worthwhile.

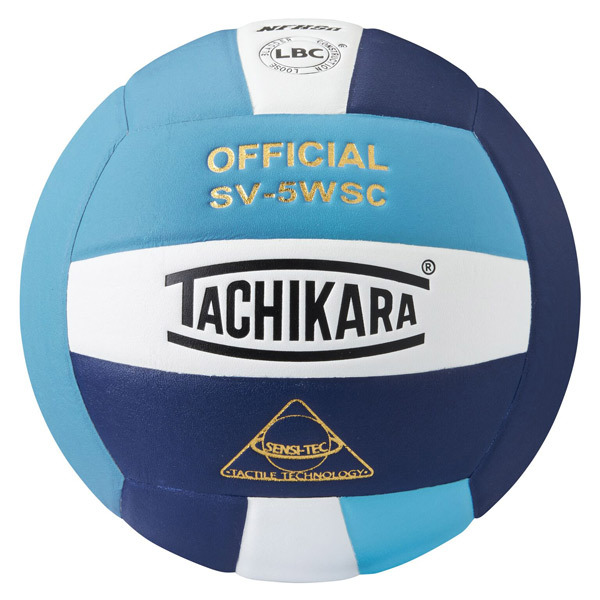

Tachikara

Tachikara is another Japanese business that has been in operation since 1915 and has been in existence for more than a century.

Despite receiving less media attention than more well-known companies like Mikasa and Molten, this brand has a devoted following of customers who keep purchasing their balls due to their high quality.

The fact that they produce a variety of balls catered to players of different ages and skill levels is one thing that sets them apart from the competition. Their balls are renowned for being soft to the touch and aerodynamic.

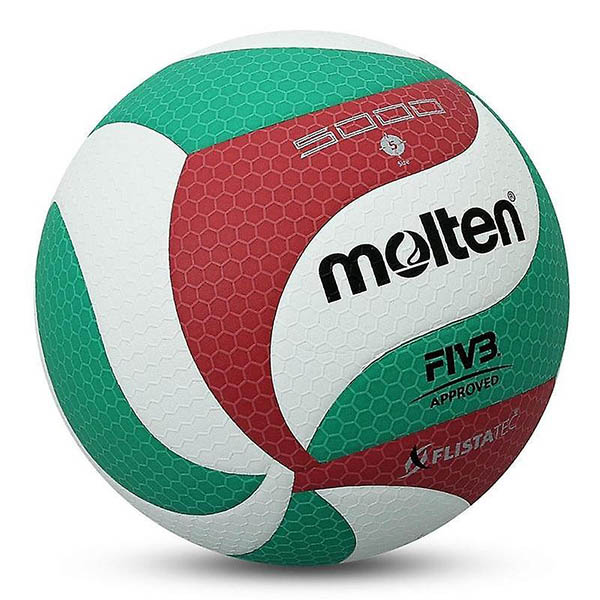

Molten

Molten sponsor the Balls for various ages and playing styles are produced by American volleyball teams. They are particularly well-liked by younger players.

Wilson

Wilson is an instantly recognised brand name, producing a wide range of equipment for a wide range of sports such as tennis, badminton, and squash. Their balls are primarily used by amateur athletes and for recreational activities.

They are also closely related to beach volleyball.

Compared to some of the other options on the market, Wilson balls are less expensive.

Spalding

Spalding is another A large variety of sports equipment is produced by an American company. While they do make balls for players of all ages, like Molten, they have a particular appeal for younger players, much like Wilson’s volleyballs are particularly suited to those who are just getting into the sport.

This is due to the fact that their balls are softer to the touch when compared to other versions that are currently on the market.

Are Rubber Volleyballs Manufactured?

Rubber volleyballs are especially made for newcomers and younger players because they are light, incredibly soft, and typically less expensive than those used by professional athletes.

A number of models come with a textured surface to enable players to get a better grip.

One example of such a ball is this model from Champion Sports (Check it Here at It is of a standard size and weight and perfect for exercising in a gym, on a beach, or in a park with friends.

It is constructed with a sturdy rubber cover so that it can withstand the demands of playgrounds or sporting venues.

In case your ball is harder than what you need, I recommend to check this article on how to soften a hard volleyball! I think you will find it helpful …

Final Thoughts

What a volleyball is made of was at the heart of the article.

It’s crucial to understand how and what materials are used to make volleyballs. This will enable you to distinguish between quality balls and average balls.

Additionally, this will assist you in selecting balls for practice or leisurely play.

Please leave a comment if you have any questions about the materials that make up a volleyball. If I see it, I’ll respond right away.

I’m grateful that you read. Thank you!